Agricultural enterprises typically calibrate grain by size, form, surface condition, aerodynamic properties, sailing capacity and other characteristics factored in the operating principles of different separators (machines or appliances).

But in order to separate grains with high biological value, like those that grown in the middle zone of a spikelet, corncob etc., you would need calibration by specific weight.

Selection of seed grain with high specific weight is key to raising crop yields and grain production.

It must be noted that the equipment for grain calibration by specific weight lags behind the requirements of the modern agricultural science and practice. Each grain cleaning machine has its specific function.

Some separators, usually large-sized, are used for preliminary and primary grain cleaning. Others are utilized for secondary, or final, grain treatment. There are also machines for separation of hard-separable impurities etc.

In combination they constitute the grain processing line. In other words, to obtain seed material conforming to national standards you must have all of these machines.

In conventional screen cleaners the imprecision of calibration is determined by their design, because the caliber of the screens differ by 0.1 or 0.2 mm.

Therefore the possibilities would be limited even for a high-qualified expert choosing the screens for certain grain crop.

Non-uniform fractions in terms of specific weight are also obtained on gravity tables, where grain being calibrated is influenced by three forces: gravitation, friction against the surface of a table and friction between seeds, which causes even greater imprecision of calibration.

MAKO aerodynamic separator from TechAgroService provides grain calibration by specific weight with 3% precision, which allows obtaining seeds with high biological value.

MAKO aerodynamic separator from TechAgroService provides grain calibration by specific weight with 3% precision, which allows obtaining seeds with high biological value.

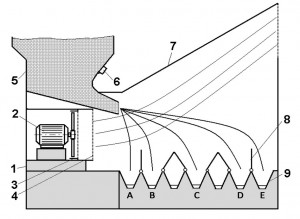

The machine consists of the frame (1), fan (2), rectifier unit (3), air flow generator (4), feeding bin (5), vibrating chute (6), working chamber (7), rotary shutters with locking units (8), seed fraction collectors (9).

In most cases MAKO machine can replace a number of machines for grain cleaning and calibration, while the provided quality of the final seed material reaches and exceeds the government standard.

The calibration occurs in the aerodynamic separator, while the seeds are falling free being blown by air flows. Each seed is affected only by air and gravitation.

Here are some major advantages of MAKO aerodynamic separator:

1. High-quality separation with any seed material.

Each grain producer wants to obtain high-quality seed material with minimum investment.

Our aerodynamic separator includes effective technology, which allows receiving high-yielding seeds.

Screenless MAKO machines were primarily designed for the preparation of the seed material.

Because seeds are precisely calibrated by specific weight, our separator allows selecting grains coming from the middle zone of a spikelet, which gives you the opportunity to raise yield by 25-35%.

2. Because of high resolving power our separators can perform primary and secondary grain cleaning regardless of the level of impurity and humidity of the ingoing material.

3. Ease of setup and use are also important for seamless machine operation. Switching from one material to another takes from 5 to 10 minutes, and doesn’t require any unit replacement.

4. Quality, reliability, durability and economic efficiency. Our machines don’t include indented cylinders, screens, chain or belt gears, or lubrication points. Minimum power costs per 1 ton of grain.

5. Proprietary technical solutions, patented in Ukraine. Learn more

6. Wide product range with various throughput capacity values (5, 10, 20, 40, 50 and 100 tons per hour) meets the requirements of both small farms and large agricultural producers, as well as elevators, poultry and feed-milling plants etc.

MAKO separators incorporate the technology that allows receiving high-yielding seeds and profit.

If you would like to obtain addresses of the farms utilizing MAKO separators, receive our DVD with materials on the efficiency of our equipment with different crops, read reviews from agricultural experts or find answers to specific questions like how our machines work and how to buy them, please feel free to contact us.